How a Rigid Box is Made

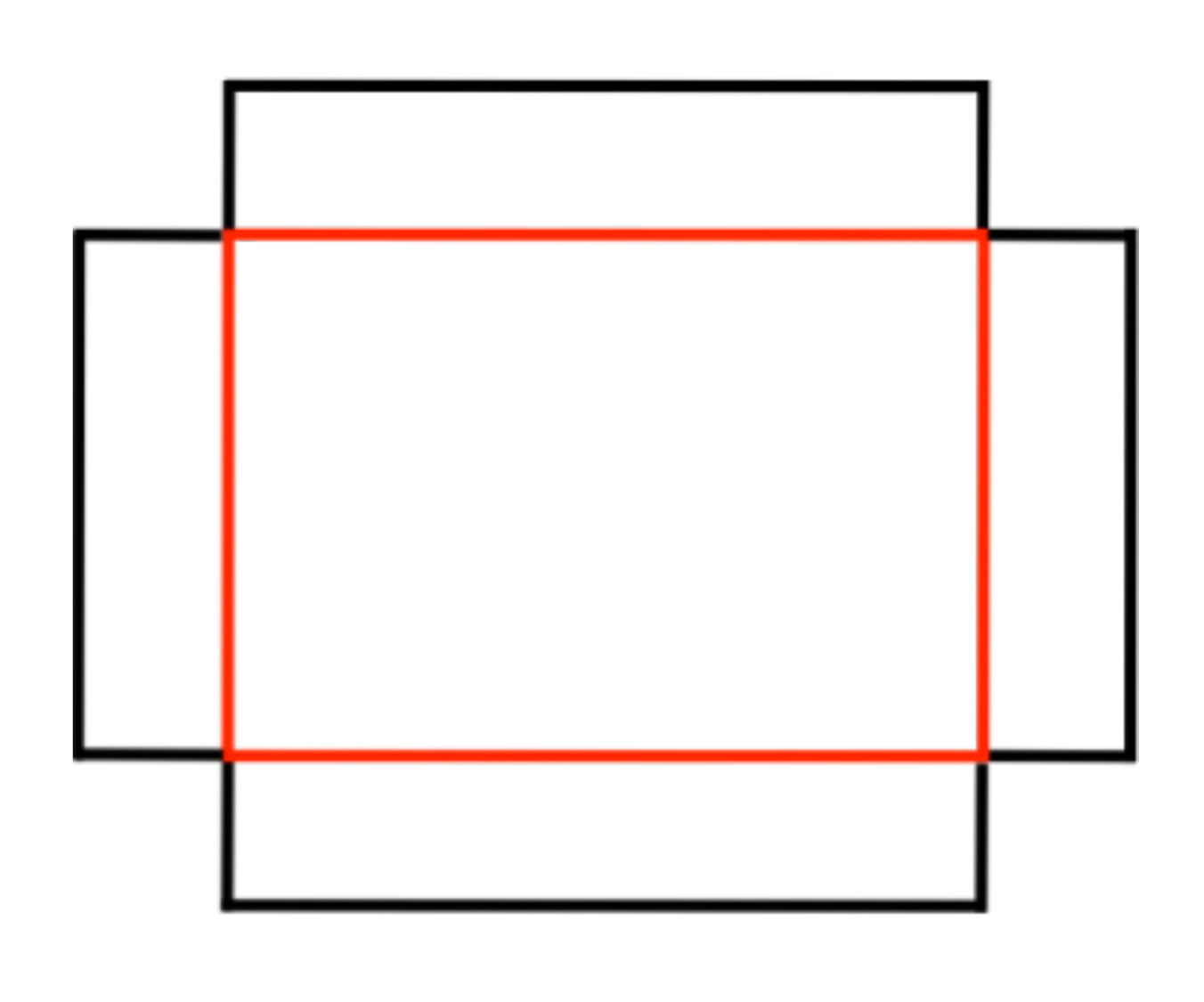

The process of creating a rigid box is very easy. It begins with non-bending cardboard and a simple steel rule die which, for a rigid box tray, contains knives (black lines) for cutting out the tray shape from the cardboard, and cut scores (red lines) that partially penetrate the board, allowing bending (scoring) without tearing. Vat-lined chip (cardboard lined on either one or both sides with a white coating made from newsprint, giving the box a more finished appearance) also works well for instances where the interior of the box is unfinished or unlined.

Not all box wraps require printing, but along with foil stamping, embossing, debossing, or other decorative techniques, the corners of all rigid box wraps must first be trimmed or “mitred” so that when the box is formed, the wrap makes a perfect transition from two-dimensional blank to three-dimensional box.